Pigment Ink Continuous Inkjet (CIJ) Printer: Rx680c

Rx680c Pigment Ink Continuous Inkjet Printer represents a high-performance segment of industrial coding and marking systems. It combines the reliable, non-contact printing technology of CIJ with the superior durability and visual properties of pigment-based inks. This combination makes it the ideal solution for applications requiring extreme longevity, resistance to environmental factors, and high-quality legibility.

Key Advantages of Pigment Inks

The defining feature of Rx680c Pigment Ink Continuous Inkjet Printer is its use of pigment-based ink, which differs significantly from standard dye-based inks:

Exceptional Durability: Pigment particles sit on the surface of the substrate rather than being absorbed like dyes. This results in outstanding resistance to:

Abrasion & Scratches: Codes remain intact during handling, transportation, and friction.

Water & Moisture: Withstands condensation, washing, and humid environments without smudging.

UV Light & Fading: Provides superior resistance to sunlight, preventing the code from disappearing over time.

Chemicals: Resists smearing from oils, solvents, and other harsh chemicals.

High Opacity and Contrast: Pigment inks are typically opaque, delivering sharp, high-contrast marks on both light and dark-colored surfaces, including directly on metals and dark plastics.

Fast Drying Times: Formulated for rapid adhesion on non-porous surfaces.

Primary Applications

Rx680c Pigment Ink Continuous Inkjet Printer is indispensable in industries where code integrity is critical for traceability, safety, and compliance throughout the product's lifecycle.

Automotive & Aerospace: Marking metal parts, wires, and components that must endure harsh conditions.

Electronics: Printing on circuit boards (PCBs), cables, and plastic casings.

Construction Materials: Coding on pipes, conduits, and metal profiles.

Beverage & Food Cans: Printing high-contrast batch codes and expiration dates on metal cans and glass bottles.

Chemicals & Agrochemicals: Coding on plastic containers and drums that may be exposed to solvents or stored outdoors.

Line speed capability

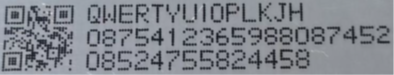

35M/min @25 dots; 138M/min @16dots

Font matrix configuration

1 line: 7x5, 9x7, 15x11, 19x15, 24x28, 33x24

2 lines:5x5, 7x5, 9x7, 11x7, 15x11,

3 lines: 5x5, 7x5, 9x7, 11x7,

4 lines: 5x5, 7x5

Printing content

Dynamic printing of 140 types of barcodes including

QR codes, DataMatrix codes.

Date, time, logo, batch number, class type, serial

number, etc. Multi language fonts.

Printing character size

1.2mm to 18mm height depending on fonts

User Interface

10.1 Inch touch screen with 1280*800dpi

WYSISWYG touch to edit print file editing

Input/Output

Sensor, Encoder, Alarm, USB, I/O , RS485, Ethernet(optional).

Ink system

Automatically measuring system for ink consumption, clear liquid level and printing parameter.

Automatic viscosity control

Automatic ink bleed control

Intelligent hydraulic system